|

Dongguan YIZE MOULD Co.,LTD

|

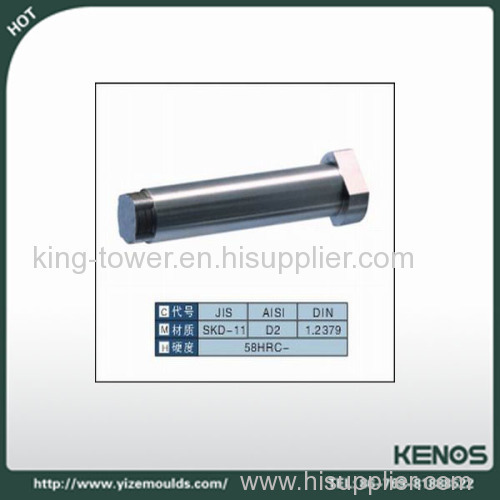

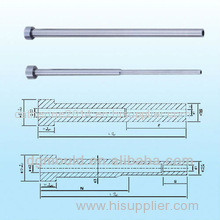

High quality precision HSS punch core pins

| Price: | 1.0~100.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.grinding/edm precision within 0.001mm

2.shape: round, rectangular, oblong, triangl

High quality precision HSS punch core pins and sleeves Briefly Description 1. mold part material brand: Hatachi, Daido, ASSAB,Buderus, Bohler,etc

2.common material used: SKD61,SKD11,SKH51,NAK80,P20;1.2343,1.1730,1.2312;S390,K460

3.Grinding precision within 0.001.EDM/wire cut precision within 0.005mm

4. milling, surface grinding, wire cutting,CNC,EDM are the main production process

5.height gauge,microcalliper,profile projector,tool microscope, comparator are the main inspection equipment

6.more than ten years' experience in this field

7. ISO9001:2008 certified factory with good quality and management

8.100% of the parts are exported to countries like Japan,USA,Europe,Southeast Aisa,etc Our Products 1)production mode : accroding to drawings and samples to process

2)material:tool steel and high speed steel,SKD61,SKD11,SKH51,etc

3)technique standard : according to national standard GM, JIS,DIN,AISI ect, and other national standard to making

4)4)technique advantage : grinding precision within 0.001mm, EDM/wire cut precision within 0.005mm grinding/EDM angle clearance within R0.01.

5)utilization scope : precision punch mold, precision plastic mold, precision auto mold, precision medical mold, precision computer connector mold and other factory automation part etc. with many areas

6)production equipment :Two sets of milling machines, two sets of CNC lathe, two sets of cylindrical grinders,one deep hole drilling machine,30 sets of surface grinders,12 sets of EDM machine,2 sets of CNC machine,4 sets of wire cut machine

7)product accuracy : diamension tolerance +-0.001mm, axiality within 0.002mm,roundness within 0.0015mm, surface roughness within Ra0.025, straightness within 0.002

8)packaging type : inner package with recycle plastic box after anticorrosive oil spraying,out package with sponge and PE bag.

9)cooperation customer : Japan,USA,Europe,Southeast Aisa,etc Production Flow

We have adopted CAD,UG and Proe system,PDF,DWG,DXF,STP,STEP,PRT,IGS files are all accepted.

30 sets of grinding machine and skilled workers enables us to make large quantity mould parts withhigh precision in a short time.Our grinding precision can be within 0.001mm.We supply to worldleaders like TE,JAE,JST,etc.

We have 4 sets of sodick wire EDM machines, it ensures general tolerance within 0.005mm,flatness,verticality,and linearity within 0.002mm.The smallest wire we use is 0.1mm.

We have two CNC machines that are mainly used to make the electrodes. Copper and Tungsten copper are the main material. Our designers design the electrode and the CNC department makes it out in house. It greatly ensures EDM quality and fast delivery. Our Services Turning, CNC turning, milling,deep hole drilling,cylindrical grinding,enterless grinding,surface grinding, wire cutting,CNC,profile grinding, EDM machining are the in-house service offered.Also polishing,laser marking,electroplating are available for us by outsource supplier. Common Questions: 1. Whether free sample can be provided? 2. Whether the quality of materials used in processing can be guaranteed? 3. How long is your delivery cycle? What method is used for delivery? Whether the good safety during transportation can be ensured? 4. What about payment terms? Can you accept cash on delivery? 5. How to deal with the parts received when they are found to be in poor quality? Yize Profile

Welcome to figure offer, the price is for reference only, we have a professional considerate service to you. Contact Yize Mould E-mail: Jack@dgyize.com |